Better Than Batteries: A Personal Power Plant

There is one aspect of personal electronics, however, that is failing to keep the pace, and that is the battery. While electronics technology is doubling in capability every 18 months, batteries governed by chemistry are doubling in capacity on a time scale of roughly 30 years. And while advances in microelectronics are helping manage power consumption, there is an ever increasing demand for faster computing, higher resolution displays, and more powerful radios to transmit and receive data increasing amounts of data, audio and video over mobile handsets (miniature computer, really.) So the poor battery has become one of the largest bottlenecks in the development of the entire consumer electronics industry.

But if MIT Professor Alan Epstein has his way, everyone will soon have a turbine in their pocket, and batteries will become obsolete. Usually, the idea of a turbine engine evokes images of jet planes and locomotives. But Alan's Gas Turbine Technology group in the MIT Microsystems Technology Lab has created a tiny engine which promises to outperform traditional battery technology in terms of power generation and fuel density.

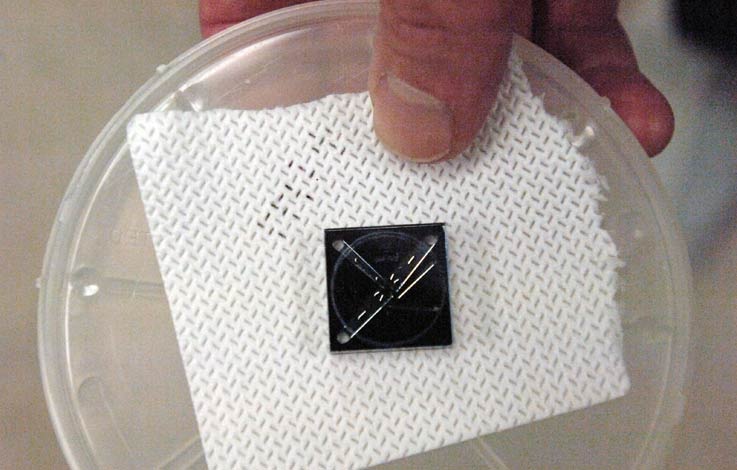

But if MIT Professor Alan Epstein has his way, everyone will soon have a turbine in their pocket, and batteries will become obsolete. Usually, the idea of a turbine engine evokes images of jet planes and locomotives. But Alan's Gas Turbine Technology group in the MIT Microsystems Technology Lab has created a tiny engine which promises to outperform traditional battery technology in terms of power generation and fuel density."How can one make a tiny fuel-burning engine? An engine needs a compressor, a combustion chamber, a spinning turbine, and so on. Making millimeter-scale versions of those components from welded and riveted pieces of metal isn't feasible. So, like computer-chip makers, the MIT researchers turned to etched silicon wafers.

"Their microengine is made of six silicon wafers, piled up like pancakes and bonded together. Each wafer is a single crystal with its atoms perfectly aligned, so it is extremely strong. To achieve the necessary components, the wafers are individually prepared using an advanced etching process to eat away selected material. When the wafers are piled up, the surfaces and the spaces in between produce the needed features and functions.

Inside a tiny combustion chamber, fuel and air quickly mix and burn at the melting point of steel. Turbine blades, made of low-defect, high-strength microfabricated materials, spin at 20,000 revolutions per second—100 times faster than those in jet engines. A mini-generator produces 10 watts of power. A little compressor raises the pressure of air in preparation for combustion. And cooling (always a challenge in hot microdevices) appears manageable by sending the compression air around the outside of the combustor."

In this case, bigger is hardly better at all.

1 comment:

One question: what sort of fuel does it use? Okay, two: if everyone ends up with one of these pups in his pocket, how much more carbon does that spit out into our globally warming environment?

Post a Comment